2 min read

Understanding the Impact of the RoHS Directive on Mercury-Based and Mercury-Free UV Lamps

Jordi Amagat Molas

:

12 Jul, 2024

Jordi Amagat Molas

:

12 Jul, 2024

The Restriction of Hazardous Substances (RoHS) Directive, enacted by the European Union, fundamentally restricts using specific hazardous materials within electrical and electronic equipment. This directive aligns with a broader commitment to environmental sustainability and public health safety by limiting substances such as lead, cadmium, polybrominated biphenyl (PBB), polybrominated diphenyl ether (PBDE), and notably, mercury, which have historically contributed to environmental degradation and health risks.

The Challenge with 254 nm UV Lamps: The Mercury Dilemma

UV lamps operating at a wavelength of 254 nm have been extensively used for their effective germicidal properties, relied upon for disinfection and sterilization processes across various industries. However, these lamps traditionally use mercury vapor to produce UV light, posing significant challenges under RoHS compliance. The inclusion of mercury, a toxic heavy metal, calls for meticulous handling and disposal processes, aligning with stringent RoHS guidelines intended to phase out mercury from electronic equipment altogether.

As mentioned in COMMISSION DELEGATED DIRECTIVE (EU) 2022/280 the date of applicability is the 24. of February 2027.

Advancing to Safer Alternatives: The Emergence of 222 nm UV Lamps

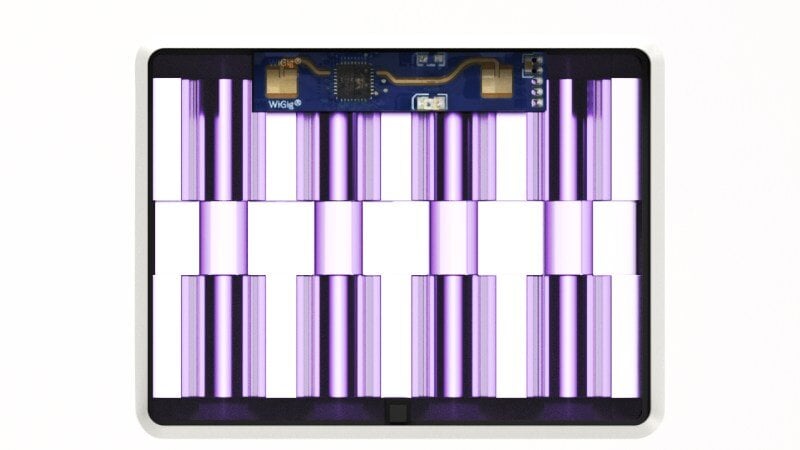

In contrast to their 254 nm counterparts, 222 nm UV lamps present an innovative and environmentally friendly solution. These lamps operate without mercury, using excimer lamps to produce Far-UVC light, effectively eliminating microorganisms while adhering to RoHS regulations. The shift towards 222 nm UV technology significantly reduces hazardous waste and enhances occupational safety, as these lamps minimize harmful exposure without compromising their germicidal efficacy.

In the broader narrative of advancing towards mercury-free UV technologies, Krypton Chloride excimer lamps emerge not merely as an alternative but as a superior choice, one that harmonizes the imperatives of microbial control, occupational safety, and environmental sustainability.

Economic Implications of Transitioning to 222 nm UV Technology

As industries strive to adapt to the stringent requirements set forth by the RoHS Directive, the economic landscape of decontamination solutions is concurrently evolving. The initial investment in 222 nm UV technology, while seemingly higher than traditional 254 nm mercury-based lamps, unfolds a panorama of long-term savings and operational efficiencies.

The durability and lower maintenance requirements of 222 nm lamps significantly reduce the total cost of ownership (TCO). Moreover, the operational expenditure declines as these lamps circumvent the need for extensive protective measures and disposal protocols associated with mercury handling. Equally important, adopting 222 nm UV technology may lead to enhanced operational productivity due to its safety profile, allowing for decontamination processes to run concurrently with human presence, thereby minimizing downtime in critical environments.

Environmental Benefits and Sustainability

By eliminating mercury, a persistent and bio-accumulative toxin, from the decontamination process, industries contribute to reducing toxic emissions and preventing mercury from entering waste streams and, ultimately, the ecosystem.

Furthermore, the enhanced energy efficiency of 222 nm lamps compared to traditional UV sources translates into reduced carbon footprints for businesses. As global attention increasingly focuses on climate change and ecological conservation, adopting technologies that support environmental protection becomes paramount.

Promoting Safety and Compliance: The Role of 222 nm Lamps in Modern Industries

The adoption of 222 nm UV technology not only facilitates compliance with stringent regulations like RoHS but also reflects an industry-wide shift towards safer and more sustainable practices. These lamps offer a pragmatic solution for industries seeking to maintain high standards of hygiene and safety without the environmental and health risks associated with mercury. Their increasing use signifies a commitment to technological innovation that prioritizes human and environmental health.

The transition from 254 nm to 222 nm Far-UVC lamps underscores a pivotal evolution in our approach to industrial safety and environmental responsibility. By embracing mercury-free UV technologies, industries can effectively circumvent the challenges posed by RoHS restrictions while contributing to a safer, cleaner world.

UV222™

UV222™ UV222 Linear

UV222 Linear UV222 Downlight

UV222 Downlight Vertex 222

Vertex 222.png) UV222 Pendant

UV222 Pendant.png) UV222 Booth

UV222 Booth.png) UV222 Step-On

UV222 Step-On.png) UV222 Cleanroom Downlight

UV222 Cleanroom Downlight UV222 Dual Downlight 60x60

UV222 Dual Downlight 60x60 UV222 Material Airlock

UV222 Material Airlock UV222 Ambulance

UV222 Ambulance UV222 Compact

UV222 Compact UV222 Industrial

UV222 Industrial