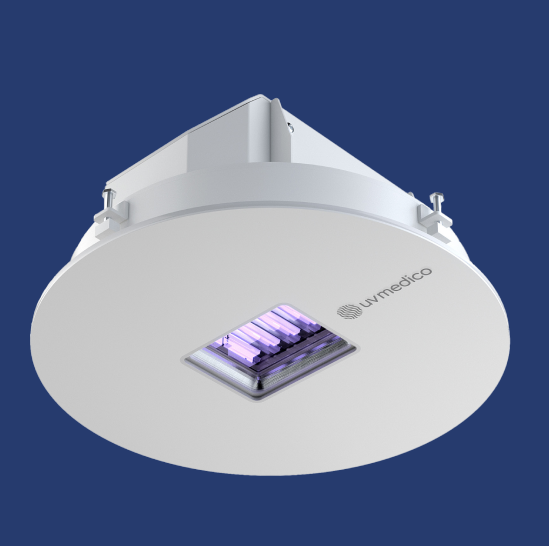

UV222 Cleanroom Downlight

The UV222 Cleanroom Downlight is specially designed for cleanroom environments to effectively minimize microbial contamination risks. It integrates seamlessly into cleanroom ceilings, providing continuous, chemical-free surface and air decontamination using advanced Far-UVC technology.

Specifically Designed for Cleanrooms

Engineered to meet strict cleanroom standards up to Class A/B (ISO 5), the UV222 Cleanroom Downlight ensures optimal compatibility across all cleanroom zones—from CNC areas to highly controlled sterile environments.

The downlight features a robust, powder-coated front module with quartz glass, securely bonded and sealed to ceiling panels using FDA-approved silicone. This advanced sealing solution provides a reliable primary barrier, crucial for maintaining the high standards of cleanliness required in contamination-controlled environments.

Key Features:

-

Far-UVC Technology (222 nm): Safe and effective microbial decontamination without harmful side effects or chemical residues.

-

Programmable Operation: Offers various operational modes, including continuous operation, duty cycles, and motion-activated functionality for flexibility and energy efficiency.

-

Active Dehumidification: Integrated solid-state electrolytic dehumidification effectively prevents internal corrosion, ensuring long-term durability and reliability.

-

Primary Seal Compliance: Inspectable and replaceable primary seal, recommended for replacement every five years, ensuring long-term compliance and reliability.

-

Seamless Integration: Flush-mounted installation compatible with various ceiling panel types, maintaining cleanroom aesthetics and airflow dynamics.

-

Robust IP65 Certification: Dust-tight and protected against powerful water jets, ensuring safe and reliable operation even under rigorous cleaning and sterilization conditions.

Ideal Applications:

-

Semiconductor and precision engineering cleanrooms

-

Healthcare facilities with stringent infection control measures

-

Advanced laboratory environments demanding high cleanliness standards

Maintenance-Friendly Design:

The UV222 Cleanroom Downlight features an easily accessible rear module, detachable via a simple screw mechanism. This simplifies routine inspection and lamp servicing, minimizing operational disruption and maintaining cleanroom integrity.

Choose UV222 Cleanroom Downlight for superior microbial control, reduced contamination risks, and enhanced operational reliability in demanding cleanroom environments.

| Light source | Krypton chloride excimer lamp |

| Wave length | 222 nm |

| Output (60° beam angle) | 115 mW (Typical) |

| Output (100° beam angle) | 70 mW (Typical) |

| Input voltage | 100-240 V AC 50/60 Hz |

| Mode | Continuous / duty cycle / motion activated |

| Max power consumption | 20 W |

| Weight | 1.6 kg (3.5 lbs) |

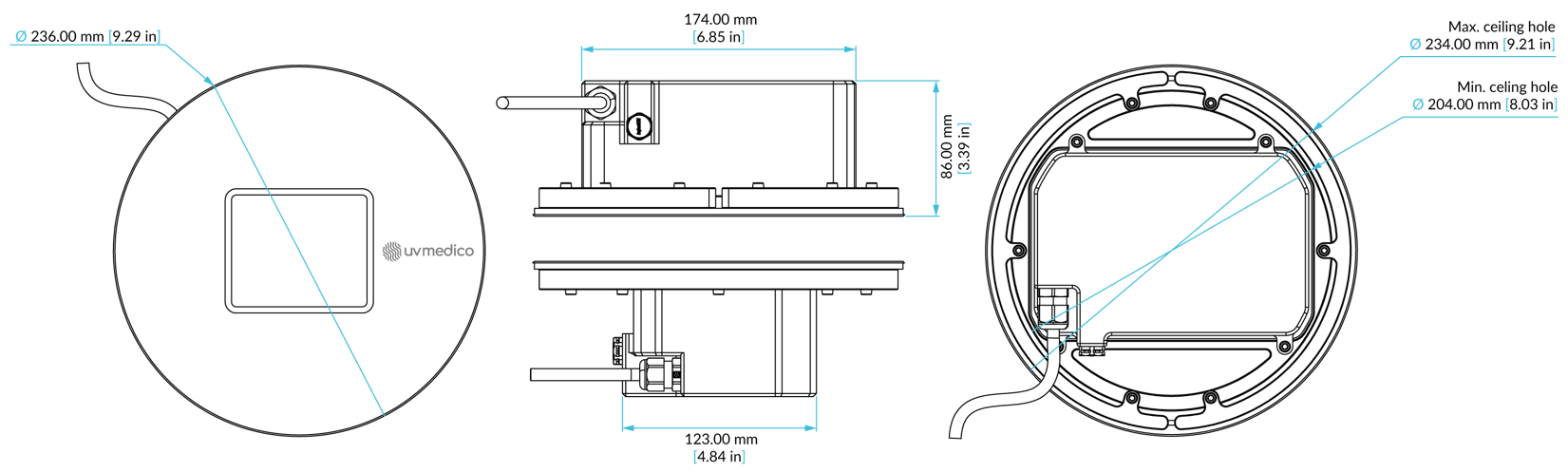

| Dimensions | ⌀ 236 mm x 100 mm (⌀ 9.29 in x 3.93 in) |

| Power lead (PVC) | 3 x 0.75 mm² / 5 m (18 AWG / 16.4 ft) |

| Operating temperature | 0° to + 50° C (32° to 122° F) |

Dimensions

Ø: 236 mm

Height: 100 mm

Do you want the Product Datasheet or the Technical & Installation manual?

Expert Insights: Latest Far-UVC Cleanroom Research & Case Studies

1 min read

Speaking at Pharmaconex: Dr. Jordi Amagat on Far-UVC for Continuous Cleanroom Decontamination

Søren Rohde: Aug 28, 2025

1 min read

UV Medico at Pharmaconex 2025 – Shaping the Future of Cleanroom Decontamination

Mohammad Fawzi: Aug 20, 2025

2 min read

Introducing the UV222 Dual Downlight 60x60: Integrated Far-UVC Decontamination for Pharma Cleanrooms

Jordi Amagat Molas: Aug 5, 2025

Request a UV222 Cleanroom Downlight Consultation or Quote Today

Should you be keen to explore the capabilities of the UV222 Cleanroom Downlight do you need a quote, just fill in your email. Our team will connect with you promptly, offering insights and support tailored to your needs.

.png?width=830&height=553&name=uvm-computer%20(1).png)

Distributors wanted in the Pharmaceutical Industry

We are looking for experienced distributors worldwide to introduce our cutting-edge Far-UVC technology to the pharmaceutical industry and cleanroom environments.

Are you interesting in learning more?

Combatting Mold with Advanced Far-UVC Solutions

Mold spores can compromise indoor air quality, triggering a range of health issues from severe allergic reactions to life-threatening infections, particularly in hospital environments. Our latest research reveals that intermittent, low-dose applications of UV222 are surprisingly effective in halting mold growth, ensuring cleaner air while maintaining safe environments for human presence. This innovative approach not only aligns with real-world usage but also opens new frontiers for maintaining health standards in medical facilities and beyond.

UV222™

UV222™ UV222 Linear

UV222 Linear UV222 Downlight

UV222 Downlight Vertex 222

Vertex 222.png) UV222 Pendant

UV222 Pendant.png) UV222 Booth

UV222 Booth.png) UV222 Step-On

UV222 Step-On.png) UV222 Cleanroom Downlight

UV222 Cleanroom Downlight UV222 Dual Downlight 60x60

UV222 Dual Downlight 60x60 UV222 Material Airlock

UV222 Material Airlock UV222 Ambulance

UV222 Ambulance UV222 Compact

UV222 Compact UV222 Industrial

UV222 Industrial