3 min read

Cleanroom operators are the main source of cleanroom contamination. Therefore, there is a need to ensure that gowned operators do not bring in contaminating particles inside the production lines. The revolutionary UV222 Booth, utilising the human-safe Far-UVC wavelength at 222 nm, reduces cleanroom excursions. Designed to be the entrance door to your high-grade areas, the UV222 Booth reduces microbial bioburden by inactivating pathogens in seconds.

Human activity remains a significant challenge in maintaining the cleanliness and integrity of cleanroom environments. Despite the use of specialised cleanroom suits, rigorous time-consuming protocols, and air filtration systems, the introduction of contamination through human-related factors is a persistent concern.

Furthermore, the high-grade classified areas face potential contamination through the shedding of skin cells, hair, and even clothing fibers by personnel. The act of movement itself can generate turbulent air currents that disperse microscopic particles throughout the cleanroom. The impact of human presence on contamination is profound, as evidenced by research which indicates that operatives in proper attire can release a remarkable 17,000 particles into the cleanroom environment per minute, from which 180 are microorganism-carrying particles [1].

Avoiding excursions, which refer to any events or activities that could lead to a breach of the cleanroom’s controlled environment, is indeed a major focus in cleanroom technologies. This includes not only following strict protocols for gowning, behaviour, and procedures, but also having measures in place to minimise human-generated disturbances within the cleanroom.

During the last decade, personnel airlocks have been using air showers as gates for the entrance to high-grade classified areas. Air showers, although efficient at removing most of the microscopic particles, can’t provide effective decontamination. Until now, a significant challenge has been posed by the presence of small biologicals and pathogens in residual smaller particles, which can remain viable and undermine cleanroom security. However, innovative equipment is already available to supplement conventional decontamination methods.

The innovation

UV Medico’s UV222 Booth is the new solution for cleanroom decontamination of gowned personnel. The UV222 Booth is available for high-grade cleanrooms and reduces the number of excursions, and within a few seconds the contaminating bioburden is reduced below detection level. The UV222 Booth works by allowing fully gowned operators to enter cleanrooms without microbial contamination on their gown, mask, goggles, or other equipment. With a fully touchless interface, operators can step into the UV222 Booth and activate it effortlessly, initiating a fast and efficient decontamination process.

Unlike conventional air showers, which involve circulation of filtered air at high speed, the decontamination process in the UV222 Booth is based on a new shade of UV light.

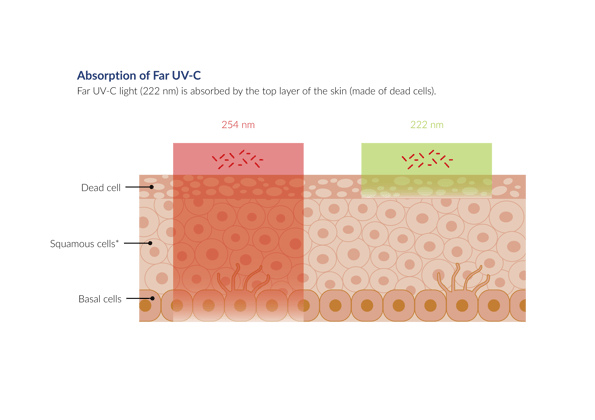

Recent breakthrough has unveiled the potential of shorter UV-C wavelengths, residing within the “Far-UVC” range, spanning 200–230 nm. Scientific research has shown that these wavelengths are unable to penetrate the outer layer of mammalian skin or the tear layer on the ocular surface and have less material degradation [2]. Among these, Far-UVC light at 222 nm, generated by filtered excimer lamps based on krypton-chloride (KrCl), presents a groundbreaking advantage. On the other hand, conventional UV-C light sources, distinguished by a prominent emission peak at 254 nm, are based on low-pressure mercury vapour discharge lamps. These lamps are effective for decontamination across air, water, and various surfaces, but are not safe to use in human presence.

Figure 1.A: Electromagnetic spectrum, from UV to visible light. B: Illustration of the human epidermis and light penetration. 254 nm light can penetrate and affect basal cells, while 222 nm UV light is absorbed by the surface layer.

Efficiency

The innovative application of Far-UVC light, and thus, the UV222 Booth, holds the potential to revolutionise decontamination practices. The utilisation of 222 nm excimer lamps marks a significant step towards creating environments that are not only clean and pathogen-free but also safe for continuous human presence.

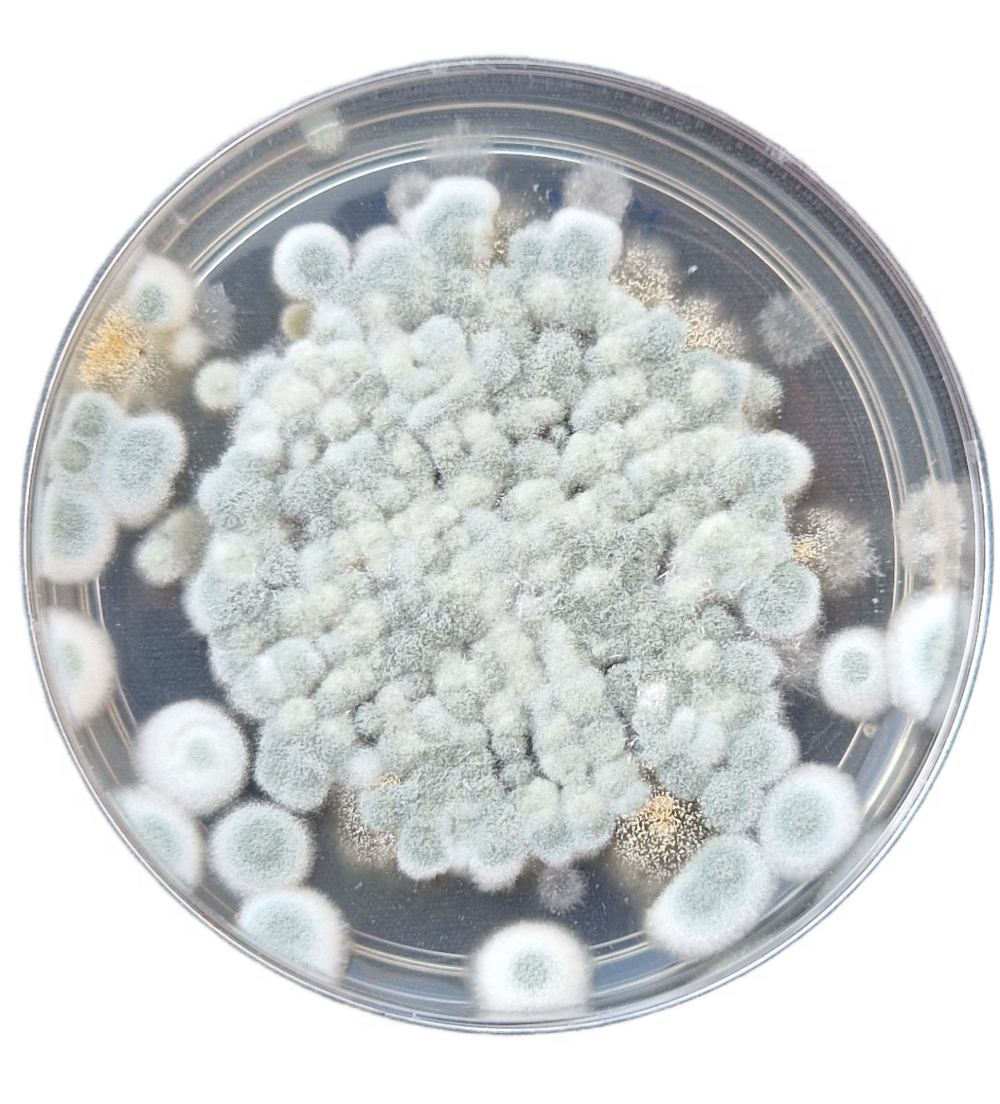

UV light at 222 nm is highly effective for inactivation of microorganisms. The antimicrobial effect of UV222 lamps has been measured and verified by independent studies and published in peer-reviewed journals [3-5]. As an example, bacteria such as Bacillus subtilis, Escherichia coli, Pseudomonas aeruginosa, Salmonella typhimurium, and Staphylococcus aureus, fungi or yeasts such as Candida albicans or Penicillium expansum, and viruses such as Adenovirus, Influenza or SARS-Cov-2 are strongly inactivated by this novel technology. With the UV Medico UV222 Booth, the contaminating bioburden is reduced below detection level in seconds.

Safety

The UV222 Booth has been developed to reduce microbial deviations caused by operators in controlled environments. The antimicrobial performance has been tested on personal protective equipment, validating a high efficacy in the decontamination of gowned personnel.

Furthermore, the UV222 Booth presents no risk to employees using the technology or other personnel nearby. Researchers reported that the transmission of Far-UVC through gowning material was remarkably low, measuring less than 0.05% for all protective equipment. Consequently, the dose of Far-UVC reaching the skin and eyes of the gowned operator during a 30-second cycle was calculated to be 0.0058 mJ/cm². This value remains well below the permissible daily exposure limit (threshold limit value), which is set at 22 mJ/cm², even with repeated usage.

In addition, the usage of the UV Medico UV222 Booth presents another upgrade for pharmaceutical, electronics, aerospace, or other high-grade industries. Environmental sustainability is a growing concern worldwide, and cleanrooms are no exception. Chemical disinfectants, although effective, come with environmental challenges and potential health risks.

Furthermore, residues from chemical disinfectants might interfere with sensitive processes, such as semiconductor or biologicals manufacturing.

The use of the UV222 Booth provides an eco-friendly and chemical-free decontamination alternative. Far-UVC light does not leave any harmful residues or contribute to environmental pollution. The technology utilises a light-based and sustainable method to eliminate pathogens, ensuring that the cleanroom remains environmentally friendly while maintaining the highest cleanliness standards.

Design and installation

Installation of the 222 nm UV booth into existing cleanrooms is relatively straightforward. These booths are designed to be versatile, allowing for easy installation in various cleanroom setups. They can be positioned in specific locations or fixed to walls and ceilings, depending on the cleanroom’s layout and requirements. Moreover, the UV222 Booth can be synchronised with the cleanroom’s automation system for optimal control and operation. This integration ensures that the UV decontamination process seamlessly aligns with the cleanroom’s workflows and protocols. Cleanroom operators can easily monitor and adjust the UV booth settings to suit different processes and operational needs.

Conclusion

The introduction of UV Medico’s UV222 Booth in cleanrooms represents a significant leap forward in maintaining cleanliness and safety while boosting productivity and efficiency. The enhanced germicidal efficacy of Far-UVC light, combined with continuous decontamination, reduces cleanroom excursions. This breakthrough technology not only helps to minimise contamination risks but also enhances employee safety, reduces environmental impact, and contributes to meeting stringent regulatory standards, such as the new EU Annex 1.

As the cleanroom industry continues to embrace this cutting-edge technology, we can expect cleaner and safer environments that will drive innovation and progress in various critical sectors. The advantages of a 222 nm UV booth in cleanrooms are clear, and its implementation marks a new era of proactive and effective decontamination in controlled environments.

References

[1] Smith, L.M. et al. (2022) ‘Identification of bacterial isolates recovered from the surface of cleanroom operators’ garments following wear’, EJPPS EUROPEAN JOURNAL OF PARENTERAL AND PHARMACEUTICAL SCIENCES. doi:10.37521/ejpps.27301.

[2] Buonanno, M. et al. (2020) ‘Far-UVC Light (222 nm) efficiently and safely inactivates airborne human coronaviruses’, Scientific Reports, 10(1). doi:10.1038/s41598-020-67211-2

[3] Goh, J.C. et al. (2021) ‘Disinfection capabilities of a 222 nm wavelength ultraviolet lighting device: A pilot study’, Journal of Wound Care, 30(2), pp. 96–104. doi:10.12968/jowc.2021.30.2.96.

[4] Welch, D. et al. (2018) Far-UVC light: A new tool to control the spread of airborne-mediated microbial diseases. Sci Rep 8, 2752. doi:10.1038/s41598-018-21058-w

[5] Kitagawa, H. et al. (2021) ‘Effectiveness of 222-nm ultraviolet light on disinfecting SARS-COV-2 surface contamination’, American Journal of Infection Control, 49(3), pp. 299–301. doi:10.1016/j.ajic.2020.08.022.

Going forward

The world of Far-UVC is wide, and custom-made Far-UVC solutions to be used in several high-grade environments can be integrated as needed. In cooperation, we will create the solution which fits the specific user needs.

UV Medico’s current range of cleanroom products does not end with the UV222 Booth. The Research and Development team is always building new solutions to achieve rapid decontamination. Thus, as operators are not the only source of contaminants, other solutions have been developed. The UV222 Material Airlock Solution gives a 360-degree decontamination and is built to neutralise potential contamination introduced during shipment, storage, and transfer of materials, trolleys, vessels, infusers, or additives in or between clean areas. In a similar manner, the UV222 Pass-Through Box offers full decontamination for smaller items which need to be transferred to areas with higher grades. The UV222 Step-On has been developed to decontaminate shoe soles, and the UV222 Downlight ensures continuous decontamination in production lines while operators perform their tasks.

Latest articles from UV Medico

Read More

Read More

2 min read

UV222™

UV222™ UV222 Linear

UV222 Linear UV222 Downlight

UV222 Downlight Vertex 222

Vertex 222.png) UV222 Pendant

UV222 Pendant.png) UV222 Booth

UV222 Booth.png) UV222 Step-On

UV222 Step-On.png) UV222 Cleanroom Downlight

UV222 Cleanroom Downlight.png) UV222 Pass-Through Box

UV222 Pass-Through Box.png) UV222 Material Airlock

UV222 Material Airlock UV222 Ambulance

UV222 Ambulance UV222 Vehicle

UV222 Vehicle UV222 Industrial

UV222 Industrial