Solve Aseptic Production Challenges with Far-UVC

Eliminate Contamination Risks & Ensure Regulatory Compliance with Continuous, Human-Safe Decontamination

The Challenge:

Maintaining Sterility in Aseptic Production

Pharmaceutical manufacturers face an ongoing battle against contamination. Despite rigorous cleaning protocols, airborne and surface pathogens remain a persistent threat to product integrity, regulatory compliance, and patient safety.

Common Challenges in Aseptic Production:

-

Residual Contamination: Even with traditional cleaning, microorganisms can persist in critical areas.

-

Human Risk Factor: Operators are one of the largest sources of contamination.

-

Manual Cleaning Limitations: Traditional disinfection requires downtime, interrupts workflows, and may not reach all surfaces.

-

Regulatory Pressure: Compliance with GMP, ISO 14644 guidelines requires stringent sterility assurance.

What If You Could Have a Continuous, Far-UVC Solution That Deactivates Pathogens Without Downtime?

-w-operator-w-shadow.png?width=542&height=600&name=UV222-Booth+Step-On-(integrated)-w-operator-w-shadow.png)

The Solution:

Far-UVC for Real-Time, 24/7 Cleanroom Protection

Far-UVC technology provides continuous, real-time decontamination to help pharmaceutical companies maintain aseptic environments without disrupting production.

Eliminates Contamination Risks – Targets and neutralizes airborne and surface pathogens before they become a problem

Safe for Human Exposure – Can be used in occupied cleanrooms without harming personnel

Reduces Human Contamination Factor – Complements gowning and air handling systems

Minimizes Downtime & Costs – No need for additional shutdowns or chemical cleanings

Ensures Regulatory Compliance – Supports GMP and ISO standards for aseptic production

Validate Before You Buy

Experience the power of UV222 technology with our "Validate Before You Buy" program. Test it at no cost to ensure it meets your decontamination and safety standards.

Cleanroom Products

How Far-UVC Solves Contamination Risks

Get all the latest news on how Far-UVC can help your aseptic production.

1 min read

Speaking at Pharmaconex: Dr. Jordi Amagat on Far-UVC for Continuous Cleanroom Decontamination

Søren Rohde: Aug 28, 2025

1 min read

UV Medico at Pharmaconex 2025 – Shaping the Future of Cleanroom Decontamination

Mohammad Fawzi: Aug 20, 2025

2 min read

Introducing the UV222 Dual Downlight 60x60: Integrated Far-UVC Decontamination for Pharma Cleanrooms

Jordi Amagat Molas: Aug 5, 2025

Protect Your Aseptic Production Today

Are contamination risks putting your production at stake? Our team can help you implement a proven, Far-UVC solution that ensures continuous aseptic conditions while maintaining efficiency.

Don’t let contamination compromise your production—take control with Far-UVC! Fill out the form and we will get back as soon as possible.

UV222™

UV222™ UV222 Linear

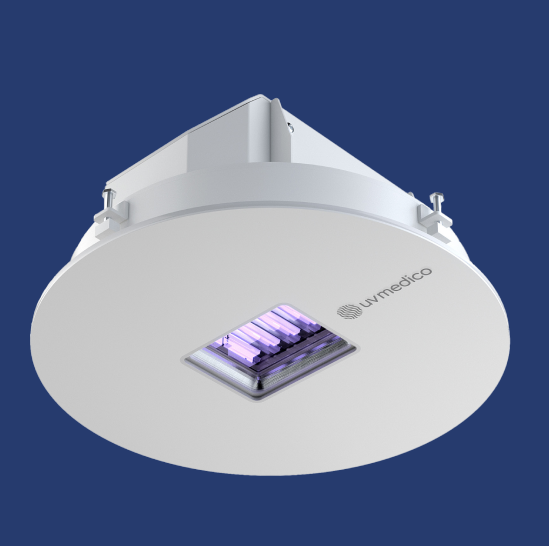

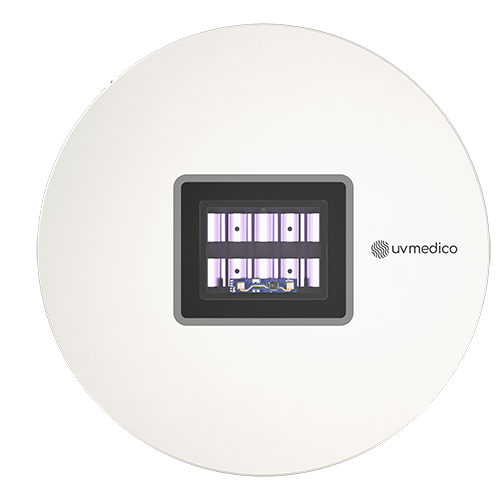

UV222 Linear UV222 Downlight

UV222 Downlight Vertex 222

Vertex 222.png) UV222 Pendant

UV222 Pendant.png) UV222 Booth

UV222 Booth.png) UV222 Step-On

UV222 Step-On.png) UV222 Cleanroom Downlight

UV222 Cleanroom Downlight UV222 Dual Downlight 60x60

UV222 Dual Downlight 60x60 UV222 Material Airlock

UV222 Material Airlock UV222 Ambulance

UV222 Ambulance UV222 Compact

UV222 Compact UV222 Industrial

UV222 Industrial

.jpg?width=550&height=550&name=Untitled%20design%20(16).jpg)