Cutting-Edge Far-UVC Solutions for Aseptic Manufacturing

Enhancing Aseptic Filling Lines

For aseptic filling lines, maintaining an environment free from contamination is critical. Our Far-UVC systems are designed to integrate seamlessly into existing facilities, providing continuous decontamination of air and surfaces. This integration ensures that your products are handled in an ultra-clean environment, thus safeguarding product integrity and patient safety

Contamination Challenges and Solutions

Challenge: Gowned Personnel introduce contamination to cleanrooms

- Gowned operators are a major source of microbial contamination in cleanrooms.

- This directly impacts the stringent sterility requirements in Grade A and B cleanrooms.

Solution and Impact:

- The UV222 Booth and UV222 Step-On prevent contamination by gowned personnel.

- Reduces microbial deviations introduced by operators in Grade A and B cleanrooms.

.jpg?width=625&height=470&name=aseptic%20filling%20line%20(1).jpg)

Challenge: Sterility in Aseptic Filling Lines

- Microbial contamination in conventional filling-line rooms is a major problem.

Solution:

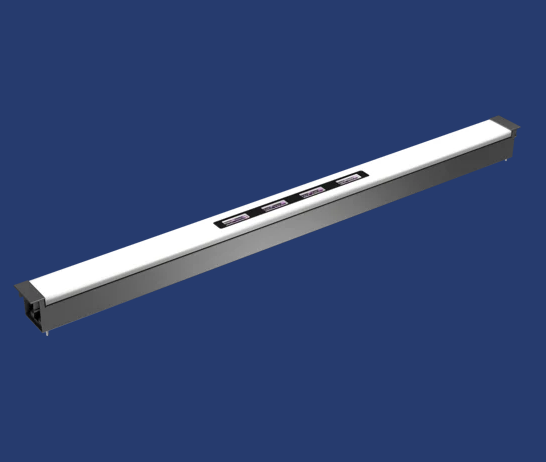

- The UV222 Linear enhances microbial control along aseptic filling lines.

- Killing of bacteria and spore-forming microorganisms continuously during

- This state-of-the-art tool boosts operational productivity.

- Seamless integration into existing laminar-airflow already installed in the ceiling.

Challenge: Transfer from Tank to Filling Line

- Aseptic coupling to filling-line inlets represents a major risk for contamination.

- Microbial presence during aseptic coupling leads discarding of batch or batch investigation.

Solution:

- The Vertex 222 creates a microbe safe-zone around the coupling to prevent contamination.

- The Vertex 222 reduces risk of introducing microbial contamination during aseptic coupling.

Decontaminate Aseptic Filling Lines with the UV222 Linear

In pharmaceutical manufacturing, especially in aseptic filling lines, maintaining a microbe-free environment is critical. The UV222 Linear brings a significant innovation by combining Far-UVC technology's decontamination power with robust lighting capabilities.

This system uses Far-UVC light to actively neutralize microorganisms in the air and on surfaces, which is essential for keeping pharmaceutical production areas sterile when products are at risk of contamination during the filling process.

Unlike traditional HVAC systems that primarily remove particulates, Far-UVC provides a continuous decontamination solution, improving safety and efficiency in production lines.

Designed to integrate seamlessly into existing cleanroom setups, the UV222 Linear meets the strict requirements of aseptic processing areas. It helps maintain low microbial counts and provides high-quality lighting to enhance operational precision.

The UV222 Linear aids in meeting and exceeding the stringent cleanliness standards of Annex 1 for grade A and B areas. Its safety profile allows decontamination with personnel present, supporting uninterrupted production and emphasizing a commitment to safety and quality.

Adding the UV222 Linear to aseptic filling lines provides a tool that not only improves microbial control but also enhances operational efficiency and clarity. This innovation underscores the commitment to leveraging advanced technologies to improve cleanroom conditions and deliver safer pharmaceutical products.

The Cost-Saving Effect of UV222 Linear Lamps

In the pharmaceutical industry, contamination during the aseptic filling process can lead to substantial financial losses. A single contamination event doesn't just result in the loss of one batch; it can also necessitate extensive cleaning, disrupt production schedules, and, in severe cases, lead to regulatory fines and damaged reputation. The financial impact of such events can run into millions of dollars, depending on the scale of the affected production and the cost of the medications involved.

Investing in preventive measures such as the UV222 Linear lamp is a strategic move to safeguard against such risks. Designed for use in environments requiring high standards of sterility, the UV222 Linear can seamlessly integrate into aseptic filling lines. It provides continuous air and surface decontamination with its Far-UVC light at 222 nm, proven to be effective in inactivating microorganisms without posing risks to human health. This technology not only helps in maintaining the microbial integrity of pharmaceutical products but also supports compliance with rigorous industry standards.

Considering the high costs associated with contamination, the UV222 Linear lamp represents a cost-effective solution to enhance aseptic processing lines. It ensures product safety and continued compliance, potentially saving companies from the financial disruptions associated with contamination incidents.

How to Comply with Annex 1 in Aseptic Filling Lines with the UV222 Linear

Annex 1 compliance in aseptic filling lines is vital for ensuring product safety in pharmaceutical manufacturing.

UV222 Linear technology can seamlessly support adherence to these stringent guidelines. It's a must-read for industry professionals aiming to elevate their operations with cutting-edge, safety-first technologies.

Latest Cleanroom Knowledge from UV Medico

1 min read

Speaking at Pharmaconex: Dr. Jordi Amagat on Far-UVC for Continuous Cleanroom Decontamination

Søren Rohde: Aug 28, 2025

1 min read

UV Medico at Pharmaconex 2025 – Shaping the Future of Cleanroom Decontamination

Mohammad Fawzi: Aug 20, 2025

Developed in cooperation with

UV222™

UV222™ UV222 Linear

UV222 Linear UV222 Downlight

UV222 Downlight Vertex 222

Vertex 222.png) UV222 Pendant

UV222 Pendant.png) UV222 Booth

UV222 Booth.png) UV222 Step-On

UV222 Step-On.png) UV222 Cleanroom Downlight

UV222 Cleanroom Downlight UV222 Dual Downlight 60x60

UV222 Dual Downlight 60x60 UV222 Material Airlock

UV222 Material Airlock UV222 Ambulance

UV222 Ambulance UV222 Compact

UV222 Compact UV222 Industrial

UV222 Industrial