UV Medico offers a solution for allowing fully gowned operators to enter cleanrooms without any microbial contamination on their gown, mask, goggles, or other equipment.

Our Far-UVC solution for healthcare facilities and hospitals offers ongoing and efficient decontamination without interrupting patient care.

Reduce the likelihood of disease spread when patients and medical personnel are in the ambulance. Our solution ensures effective decontamination of the patient area.

Airborne diseases constantly threaten public health. Combat these risks effectively by enhancing indoor air quality with the installation of UV222.

Transferring equipment between cleanroom zones is a critical point of vulnerability in contamination control. The UV222 Material Airlock is designed to address this challenge by providing a validated, chemical-free decontamination process for materials and equipment—ranging from small tools to large vessels—before entering higher-grade cleanroom zones.

By utilizing Far-UVC (222 nm) light, the system ensures rapid microbial decontamination of both air and exposed surfaces without damaging sensitive materials or generating particles. Unlike traditional methods, there is no need for chemical residues or manual handling, making the airlock an ideal solution for GMP-compliant workflows.

Rapid, residue-free decontamination of equipment surfaces using scientifically documented UV222 technology.

Non-damaging to materials, ensuring no degradation of plastics, metals, or coatings over time.

No particle generation, preserving ISO 14644 cleanroom classifications.

Integrated barrier function, preventing cross-contamination between cleanroom zones.

Optimized for large equipment, including vessels, carts, and tools used in sterile production environments.

The UV222 Material Airlock is particularly suited for:

Pharmaceutical production where cleanroom zoning and aseptic workflows are critical.

High-grade manufacturing facilities adhering to Annex 1 guidelines and contamination control strategies (CCS).

The airlock utilizes excimer-based Far-UVC lamps strategically placed to cover equipment surfaces from multiple angles. As equipment enters the chamber, a preset cycle activates the UV222 light to inactivate microorganisms in seconds. The process is fully automated, ensuring consistent results with minimal operator involvement.

| Light source | Krypton chloride excimer lamp |

| Wave length | 222 nm |

| Average irradiance (at centre) | 250 µW/cm² † |

| Dose in 15 min. (at centre) | 225 mJ/cm² † |

| Input voltage | 85-305V AC 50/60 Hz |

| Mode | 15 min. duty cycle or until stopped by user † |

| Max power consumption | 2.1 kW |

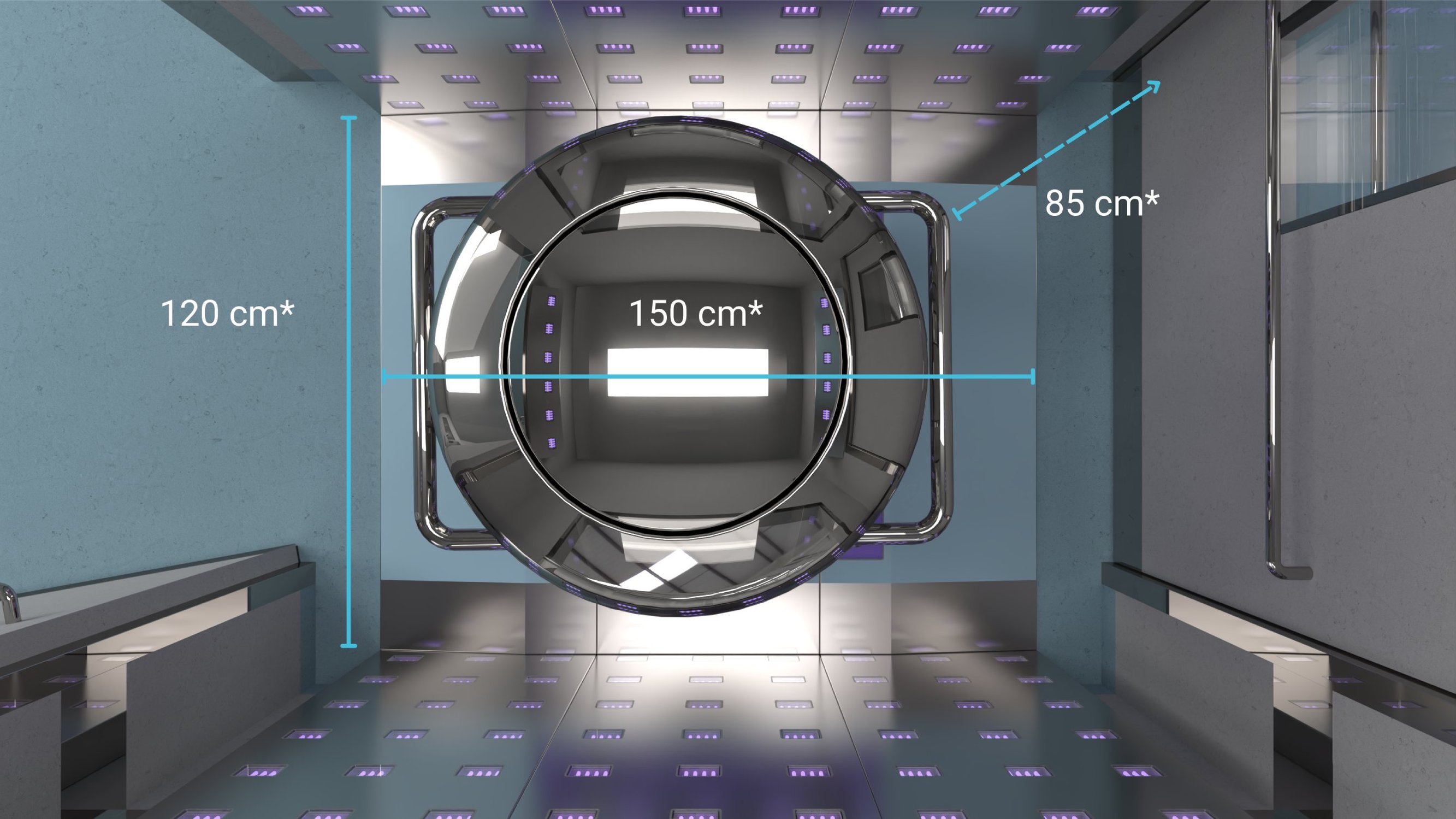

| Dimensions – inside | L150 x W120 x H80 cm (5.9 x 3.9 x 2.8 ft) † |

| Dimensions – outside | L220 x W150 x H110 cm (7.2 x 5.9 x 3.6 ft) † |

| Operating temperature | 0° to +50° C (32° to 122° F) |

† Values based on a standard UV222 Material Airlock with 127 Far UV-C light sources.

The UV222 Material Airlock can be customised upon request.

■ UV222 Far-UVC excimer lamp with an optical band-pass filter

■ A typical krypton chloride 222 nm Far-UVC excimer lamp without an optical band-pass filter

WARNING!

Unfiltered Far-UVC can cause cancer and may increase the risk of cataracts.

The dimensions are based on a standard UV222 Material Airlock, and the product can be customised to fit specific needs.

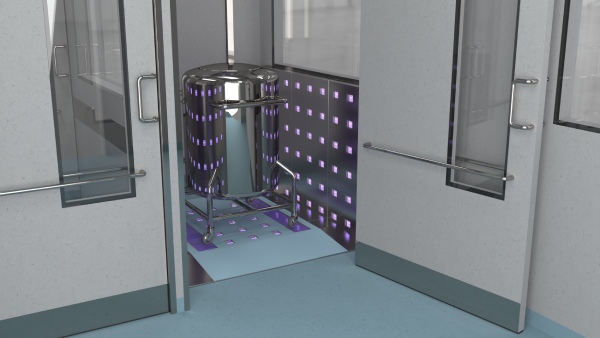

The UV222 Material Airlock is designed for easy installation and maintenance between cleanroom grades. The surface is accessible for cleaning and can be ordered in one of two types of medical-grade stainless steel (304L or 316L), renowned for their strength, durability, and corrosion resistance.

Apr 22, 2025 by Emilie Hage Mogensen

Should you be keen to explore the capabilities of the UV222 Material Airlock or do you need a quote, just fill in your email. Our team will connect with you promptly, offering insights and support tailored to your needs.

.png?width=830&height=553&name=uvm-computer%20(1).png)

We are looking for experienced distributors worldwide to introduce our cutting-edge Far-UVC technology to the pharmaceutical industry and cleanroom environments.

Are you interesting in learning more?

UV Medico is proud to introduce an advanced disinfection technology: mercury-free, 222 nm Krypton-Chloride (KrCl) excimer lamps. These innovative lamps offer a safe, sustainable alternative to traditional mercury-based systems, aligning with modern environmental and health standards. Ideal for cleanroom environments, KrCl lamps assure high-level disinfection efficacy without compromising human or ecological safety.