Far-UVC Cleanroom Solutions

Substantial reduction of cleanroom excursions

Allow gowned operators to enter and remain in cleanrooms without any microbial contamination.

Continuous Microbial Reduction in the Presence of People

Inactivation of airborne viruses up to 99.9%, including SARS-COV-2.

Air Changes Equivalents per hour (eACH)

Reduces spread of infection of colds, flu and other viruses. Read more.

Mercury-Free and Environmentally Friendly

Zero Mercury, no chemicals, 12 watt power consumption and UL867 Ozone Compliant. Read more.

Product Lifetime

Our technology exceeds the industry lifetime standards by more than 13.000 hours.

Cleanroom Products

Full decontamination of gowned Cleanroom operators in seconds

Within seconds, the UV222 Booth reduces contamination of the cleanroom operator to levels below detection. By minimizing the risk of operators introducing contamination into the cleanroom environment, the incidence rate of excursions is lowered substantially.

Around 80% of cleanroom excursions originate from the human operators. The UV222 Booth effectively reduces this problem.

Introducing Mercury-Free Far-UVC Technology with KrCl Lamps

UV Medico is proud to introduce an advanced germicidal technology: mercury-free, 222 nm Krypton-Chloride (KrCl) excimer lamps. These innovative lamps offer a safe, sustainable alternative to traditional mercury-based systems, aligning with modern environmental and health standards. Ideal for cleanroom environments, KrCl lamps assure high-level decontamination efficacy without compromising human or ecological safety.

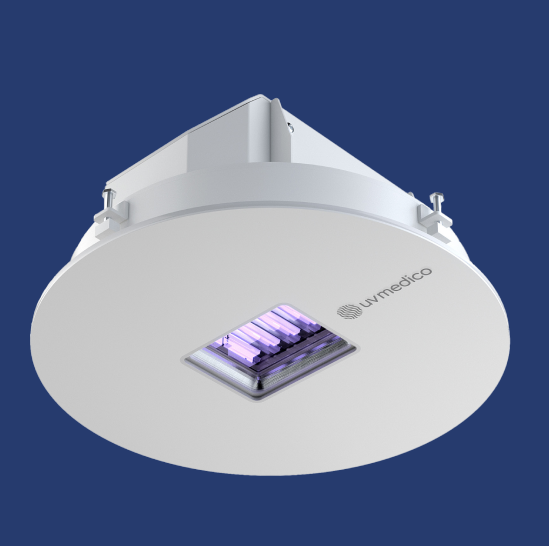

UV222 Cleanroom Downlight reduces microbial contamination in all areas

The UV222 Cleanroom Downlight meets all cleanroom installation requirements up to class A/B and is designed to be installed in every single area of your cleanroom, from CNC to A/B areas. This includes the need for a primary seal, which can be inspected and replaced every 5 years for maintenance.

The front module of the lamp is oriented towards the cleanroom area, serving as a ceiling insert that seamlessly fits various types of ceiling panels. It is powder-coated, and features quartz glass bonded and sealed to the ceiling panel using FDA-approved silicone. To access the lamp for maintenance, the back module can be unscrewed from your service hatch.

Customised solutions for any cleanroom

The UV222 Booth is designed to be versatile, allowing for easy installation in existing cleanrooms.

By synchronising the UV222 Booth with the cleanroom’s automated system, the decontamination process can be aligned seamlessly with existing workflows and protocols. It can be positioned in specific locations to suit the layout and requirements of the cleanroom.

Do you want to know more about the UV222 Booth?

Decontaminate cleanroom shoes with the UV222 Step-On

Cleanroom personnel are trained to minimize contamination by following strict protocols and wearing specific protective equipment. This includes wearing specially designed cleanroom shoes, which are easy to clean, secure stability, and are often made of a non-shedding fabric.

Although the shoes are easy to clean, they still represent a risk of contamination, when personnel put on their shoes and move through different cleanroom areas.

The UV222 Step-On is touchless, chemical-free, and a fast and effective way of decontaminating the entire outsole of the shoes, reaching areas inaccessible to sticky mats and wipes.

Latest Cleanroom News from UV Medico

3 min read

How a New Light Emerged: The Rise of Far-UVC in Disinfection Science

Apr 22, 2025 by Emilie Hage Mogensen

3 min read

Far-UVC and ISO 14644 Compliance in Cleanrooms

Mar 14, 2025 by Jordi Amagat Molas

2 min read

New Study Highlights UV222 Lamp in Safe Pathogen Inactivation

Feb 27, 2025 by Ping Hu

UV222™

UV222™ UV222 Linear

UV222 Linear UV222 Downlight

UV222 Downlight Vertex 222

Vertex 222.png) UV222 Pendant

UV222 Pendant.png) UV222 Booth

UV222 Booth.png) UV222 Step-On

UV222 Step-On.png) UV222 Cleanroom Downlight

UV222 Cleanroom Downlight UV222 Material Airlock

UV222 Material Airlock UV222 Ambulance

UV222 Ambulance UV222 Industrial

UV222 Industrial

.jpg?width=550&height=550&name=Untitled%20design%20(16).jpg)